Fiber Reinforced Composite Bearings

High Load Self-Lubricating Bearings

GGB-MEGALIFE™ XT

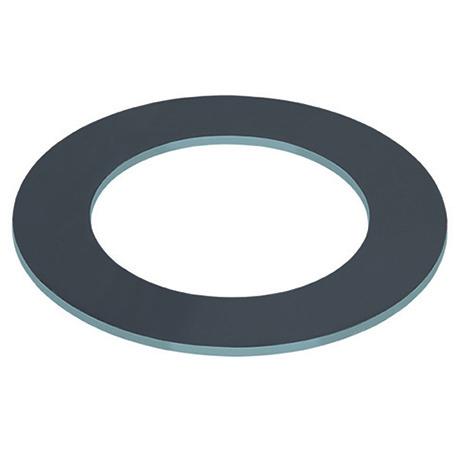

Fiber Reinforced Composite PTFE Thrust Washer

CHARACTERISTICS

- Proprietary filled PTFE tape liner on both surfaces

- Excellent shock resistance

- High load capacity

- Excellent misalignment resistance

- Excellent contamination resistance

- Good surface speed capability

- Very good friction and wear properties

- Good chemical resistance

Bearing forms available in standard dimensions

Bearing forms made to order: cylindrical bushes with non-standard lengths and wall thickness, flanged bearings, hexagonal and square bores, liner on outer diameter, customized bearing designs

STRUCTURE AND COMPOSITION

Composite Thrust Washer

Proprietary filled PTFE tape liner on both

sides + continuously woven layer of filament

glass fiber encapsulated in a high temperature

epoxy resin

MICROSECTION

| OPERATING PERFORMANCE | |

| Dry | Very Good |

| Oil lubricated | Fair |

| Grease lubricated | Poor |

| Water lubricated | Very Good |

| Process fluid lubricated | Fair |

| FOR SUPERIOR PERFORMANCE | |

| Oil lubricated |

HPF |

| Grease lubricated |

DX |

| Process fluid lubricated |

HPF |

Nothing changes except the name of the GGB bearing material: to better fight against counterfeiting, GGB has changed MEGALIFE XT (also known as Megalife) into GGB-MEGALIFE™ XT.

BEARING PROPERTIES

| GENERAL | Unit | Value | |

| Maximum load, p |

Static Dynamic |

N/mm2 N/mm2 |

140 140 |

| Operating temperature |

Min Max |

°C °C |

– 195 175 |

| DRY | |||

| Maximum sliding speed, U | m/s |

0.5 |

|

| Maximum pU factor |

|

N/mm2 x m/s |

1.23 |

| Coefficient of friction |

0.02 – 0.12 * |

| RECOMMENDATIONS | |||

| Shaft surface roughness, Ra |

|

µm |

≤ 0.4 |

| Shaft surface hardness |

|

HB |

> 200 |

* Depending on operating conditions

BEARING PROPERTIES

| GENERAL | Unit | Value | |

| Maximum load, p |

Static Dynamic |

psi psi |

20 000 20 000 |

| Operating temperature |

Min Max |

°F °F |

– 320 350 |

| DRY | |||

| Maximum sliding speed, U | fpm |

100 |

|

| Maximum pU factor |

|

psi x fpm |

35 000 |

| Coefficient of friction |

0.02 – 0.12 * |

| RECOMMENDATIONS | |||

| Shaft surface roughness, Ra |

|

µin |

≤ 16 |

| Shaft surface hardness |

|

HB |

> 200 |

* Depending on operating conditions

TYPICAL INDUSTRY APPLICATIONS

Agriculture

Construction

For manufacturers of construction and other off-highway equipment, GGB fiber reinforced composite bearings are a greaseless, maintenance-free solution with an extended service life

Mining

Materials Handling

Custom Lengths Available

Thyssing can supply custom lengths upto 410mm long free of charge.

Metric and Imperial Sizes

Both Metric and Imperial sizes are available to achieve the design requirements.

Australian Stock

Thyssing keep a wide range of stock here in Australia to reduce lead time for customers.

Low Maintenance

Garmax Bushes are Self lubricating so you can save time and money on maintenance.

We're here to help!

Please do not hesitate to contact us with any design enquiries. Our experienced engineers are ready to help you with any enquiries and are willing to assist you with support to make sure you get the right product for your application.

Address

33 Nevin Drive, Thomastown VIC 3074

Office Hours

M-F: 9AM - 5PM

Phone

(03) 9464 2950

Contact Us

Fill out the below contact form and our team will be in touch with your to assist with your enquiry.